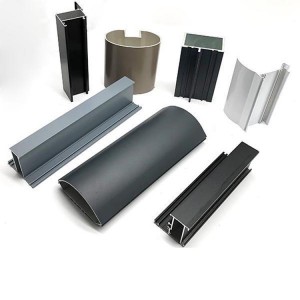

Powder Coating Aluminium Profile

Product Detail

Product Tags

The advantages of Powder Coating Aluminium Profile

1.Light and energy saving

2.Various colors for choice

3.Easy to fabricate and clean

With the continuous development of powder coating technology, electrostatic powder coating on the surface of aluminium profile is widely used by the current powder coating technology due to its unique advantages. The main features are recycling rate of more than 95%, no pollution to the environment, powder coating under normal temperature conditions without pre-heating, thick film layer can be formed at one time, no hanging phenomenon and so on.

The powder coating aluminium profile is sprayed on the surface of with an electrostatic powder spraying device. Under the action of static electricity, the powder will be uniformly adsorbed on the surface of the aluminium profile to form a powder coating, varying final coatings. The spraying effect far exceeds the painting process in terms of mechanical strength, adhesion, corrosion resistance and aging resistance.

The powder coating aluminium profile uses powder to coat, and the process uses electrostatic spraying. Using the effect of the friction spray gun, under the influence of the accelerated wind, the powder particles carry a positive charge when sprayed out of the gun body, and come into contact with the negatively charged profile to produce It is electrostatically adsorbed and then cured at high temperature. It also enhances the paint’s adsorption strength and prevents the paint film from falling off.

From the point of view of the process itself, it has a relatively high technological content and mixed paints with different colors to produce decorative effects in different colors. It is more in line with the needs of interior decoration, and is also in line with the trend of aluminium profile in the construction industry’s development toward interior Consistent. In particular, the combined use of powder coating aluminium profile and thermal break bridges makes it more fashionable, and powder coating aluminium profile have greater development space, which is also irreplaceable for profiles produced by other processing methods.

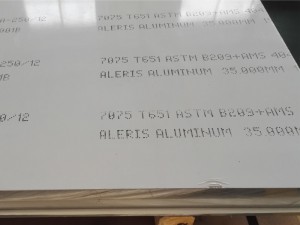

| Product | Powder Coating Aluminium Profile | |

| Aluminum Alloy | 6063, 6063A, 6061, 6463, 6463A, 6060, 6005, 6082, etc. | |

| Temper | T4, T5, T6 | |

| Quality Standard | China National Standard GB/T 5237-2008 (High Precision Class), China National Standard GB/T 6892-2006(High Precision Class) | |

| Quality Certificate | ISO 9001:2015, ISO 14001:2015, CQM Certification | |

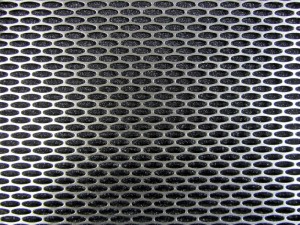

| Application | Aluminum window and door frames, curtain walls, railings, furniture decoration, heat sinks, industrial parts, railway vehicles, etc. | |

| Surface Treatment | Anodizing: Silver, champagne, bronze, black, gold, titanium, imitating steel, etc. | |

| Electrophoresis: Sliver, champagne, black, golden, titanium, etc. | ||

| Power coating: RAL normal color, or customize customer color samples | ||

| Polishing: Mechanical polishing or chemical polishing | ||

| Wood Imitation: Normal wooden color or customized wooden color | ||

| Fluorocarbon Coating: AkzoNoble color or customize customer color samples | ||

| Deep Processing Ability | Drilling, punching, bending, CNC, aluminium alloy profile fabrication, Precise cutting etc. | |

| MOQ | 500 kgs to 3,000 kgs | |

| Packing Details | Protection film and hot shrink plastic film / EPE foam packing / brown paper packing / wooden packing / Metal pallet or depend on clients special requirement. | |

| Payment Term | 1) T/T: 30% of total value as deposit by T/T within 3 days to confirm the order, and the balance to be paid by T/T before loading the container. | |

| 2) L/C: 30% of total value as deposit to be paid by T/T within 3 days to confirm the order, and the balance to be paid by L/C at sight after loading the container. | ||

| 3) Big order: Pay 30% of total value as deposit by T/T within 3 day to confirm the order, and the balance to be paid by T/T after delivery against the copy of B/L. | ||

| Shipping Methods | Ocean shipment, air shipment, land transportation and multi-transportation, etc. | |