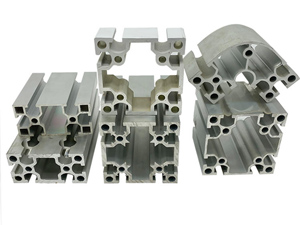

Modular aluminum framing

Product Detail

Product Tags

modular aluminum framing is used for a wide range of framing applications. All the modular aluminum framing have inclined groove flanks engineered into the profile designs, which ensured modular connections take advantage of the controlled elastic deformation, maximizing the strength of each connection. Therefore, those profiles can be used for any number of structural applications, and require no welding or special tools for assembly.

Shanghai bozhong metal group Co., Ltd mainly manufactures architectural construction profile like windows, doors, curtainwall since it was established. But due to the development of our company strength and the expansion of our technician teams, R&D Team, different kinds of industrial profiles have been come out and improved nowadays. A modular aluminum framing is one of the industrial profiles which Guangyuan has spent much effort on researching, testing, and improving. Although Guangyuan does not have a system catalog for modular aluminum framing, we are developing and generating step by step to complete it. As a premium aluminum extrusion factory, we provide various shapes or types of profiles, likes, solid, semi-hollow and hollows.

The Benefits of Modular aluminum framing are:

1. Modular aluminum framing has a wide range of usage in home decorate or construction areas

2. Because of the nature of aluminum alloy profile, Modular aluminum framing is lightweight durable and sustainable

3. Modular aluminum framing works really well in conjunction, and it’s simple and easy to assemble.

4. Modular aluminum framing can be customized and it offers a stylish, modern and aesthetic design

Common applications of Modular aluminum framing are:

1. workstations

2. machine bases and enclosures

3. medical manufacturing

4. material handling carts

5. stairs and platforms

The advantages of Modular aluminum framing Light and energy saving

Easy to fabricate and clean

Long operating Life and durable

|

Product Description |

|||

| ITEM |

Modular aluminum framing |

||

| Material | 6000 series aluminium alloy | ||

| Temper | T4, T5, T6 | ||

| Profile Thickness | 0.5mm ~ 20mm | ||

| Surface Treatment | Mill finish, anodizing, electrophoresis, powder coating, wooden color, fluorocarbon coating, polished, brushed, etc. | ||

| Coating Film Thickness | 8~25um for anodizing film, 40~120um for powder coating film | ||

| MOQ | 500kgs for each item | ||

| Packing Details

|

Inside: Packed with protection film to protect the surface of each profile | ||

| Outside: Wrapped with hot shrink film and waterproof craft paper | |||

| Settlement Term | Calculate by actual weight or theoretical weight in the drawing | ||

| Delivery Time

|

Die Tooling & Sample Testing: 7-15 days | ||

| Mass Production Completed: 15~25 days after samples are confirmed by the buyer | |||

| FOB Port | Guangzhou / Shenzhen / Foshan | ||

| Payment Term | T/T 30% for deposit and 70% for balance before shipping | ||

| Production Capacity | 12,500 tons monthly and 150,000 tons annually | ||

| Certificate and Standard | CQM, ISO, SGS, BV | ||

| Guarantee | Surface finish can be stable for 10~20 years for indoor usages | ||